Chemical analysis is used to identify the contents, composition quantity and quality of the materials used in product development, manufacturing and in-service support activities.

A Charpy impact test, also known as the Charpy V-notch test, is a destructive method that measures a material’s toughness, the ability to absorb energy, and resistance to brittle fracture.

The tensile test are performed at ambient temperatures and high temepratures to determine the mechanical properties of the material under test, in order to ascertain its compliance with the reference standards.

Creep testing is critical to understanding and preventing product failures. Element performs both stress rupture and creep testing for metals to determine the long-term stress on materials.

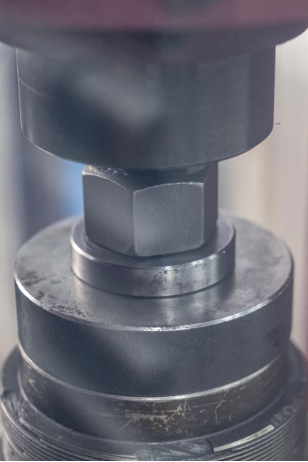

Proof load is an amount of force that a fastener must be able to withstand without permanently deforming.

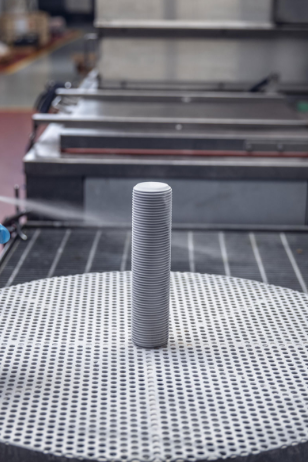

A salt spray test is a corrosion testing method that uses high-saline environments to measure the corrosion resistance of products, paints and coatings over extended periods.

Ultraviolet exposure (UV testing) is performed to understand how a material will withstand the damaging effects of ultraviolet exposure, which can cause significant changes to the properties and useful life of a material.

Microhardness Testing is a method of determining a material’s hardness or resistance to penetration when test samples are very small or thin, or when small regions in a sample are to be measured.

Macroscopic examination, also called Macro Test or Macro Examination, evaluates the quality and consistency of a test sample using only low or no magnification. The macro examination of steels is used to evaluate the macrostructural properties of a sample, which can include the detection of defects in the origin matrix, segregations, central macro segregations and any presence of discontinuities..

The microstructure analysis is performed on steels and alloys in order to ensure that the morphological properties, required by the reference standards and any additional customer requirements, fall within the established parameters. The analysis is performed to determine that the heat treatments performed have conferred the expected metallurgical requirements.

Magnetic particle Inspection (MPI) is a non-destructive testing process for detecting surface discontinuities in ferromagnetic material.

Ultrasonic testing (UT) is a non-destructive test method that performed to detect cracks and defects in parts and materials. It can also be used to determine material’s thickness.

Dye penetrant testing is utilized to locate indications on the material surface. A highly penetrating dye on the surface enters discontinuities after a sufficient penetration time due to capillary action, and after removing the excess dye with a developing agent, the defects on the surface will be visible.

Visual Testing (VT) is based on the inspection for flaws that are visible to the naked eye and is the most commonly used NDT method across all industries. It allows for a feasible and fast control of quality at every step of the production process.

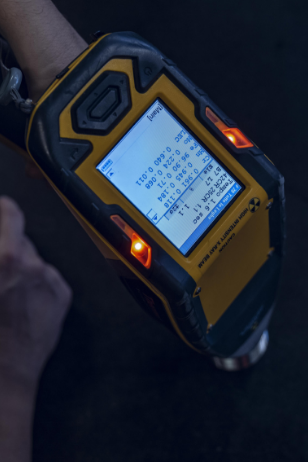

Positive Material Identification (PMI) is a fast and non-destructive method for verifying the chemical composition of metals and alloys. Portable and fast, PMI can be performed in our lab, or in the field.

Ferrite testing is a accurate process that measures the percentage of ferrite in stainless steel–specifically austenitic and duplex stainless steel.

Hardness is a characteristic that applies to a range of materials—metals and nonmetals alike—and is defined as the resistance of the material to deformation, penetration, scratching, or other physical force. OME's experts measure hardness according to the requirements of the material and its applications, with equipment precisely calibrated to the appropriate hardness scales.